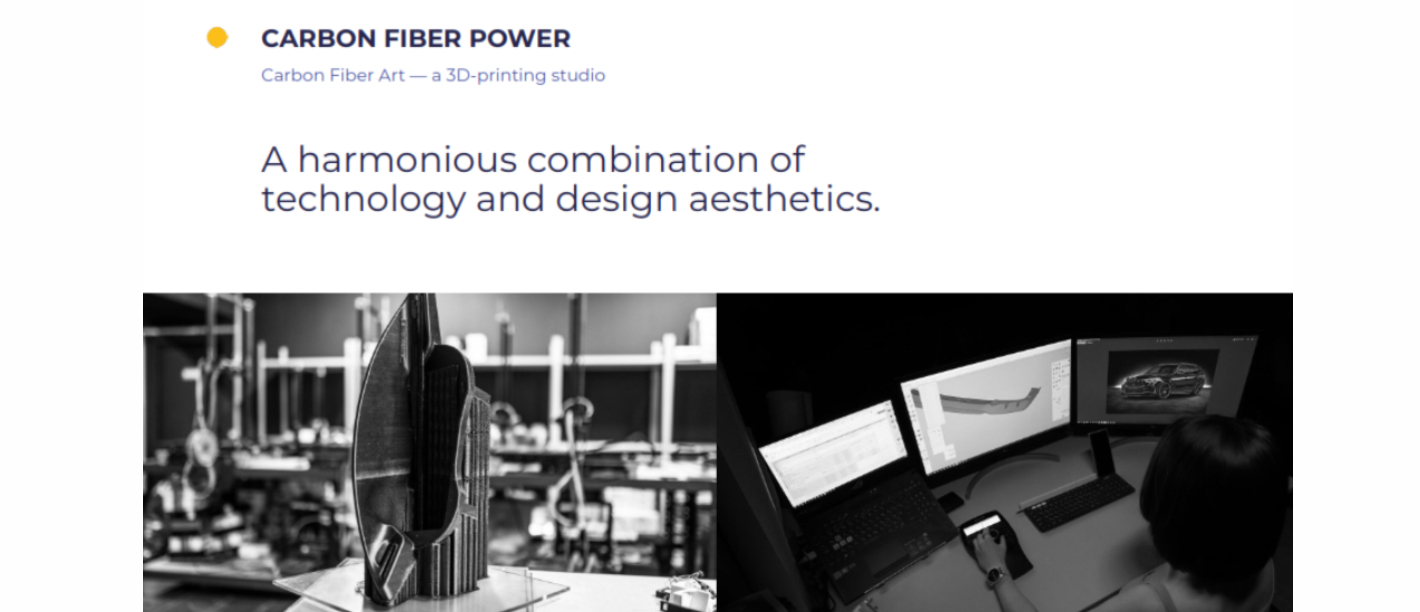

AUTOMOTIVE INDUSTRY

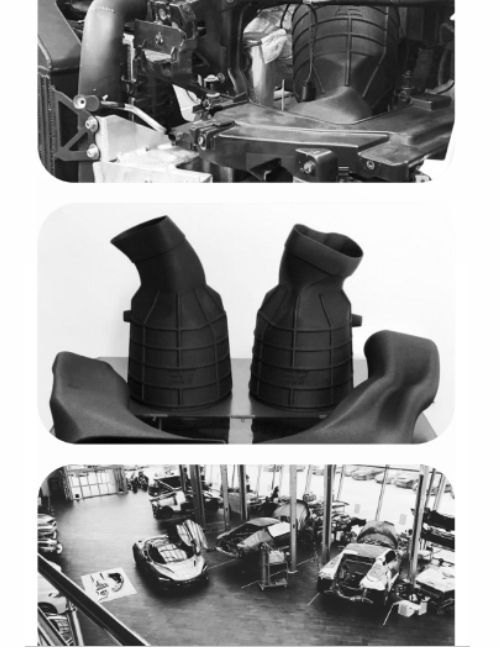

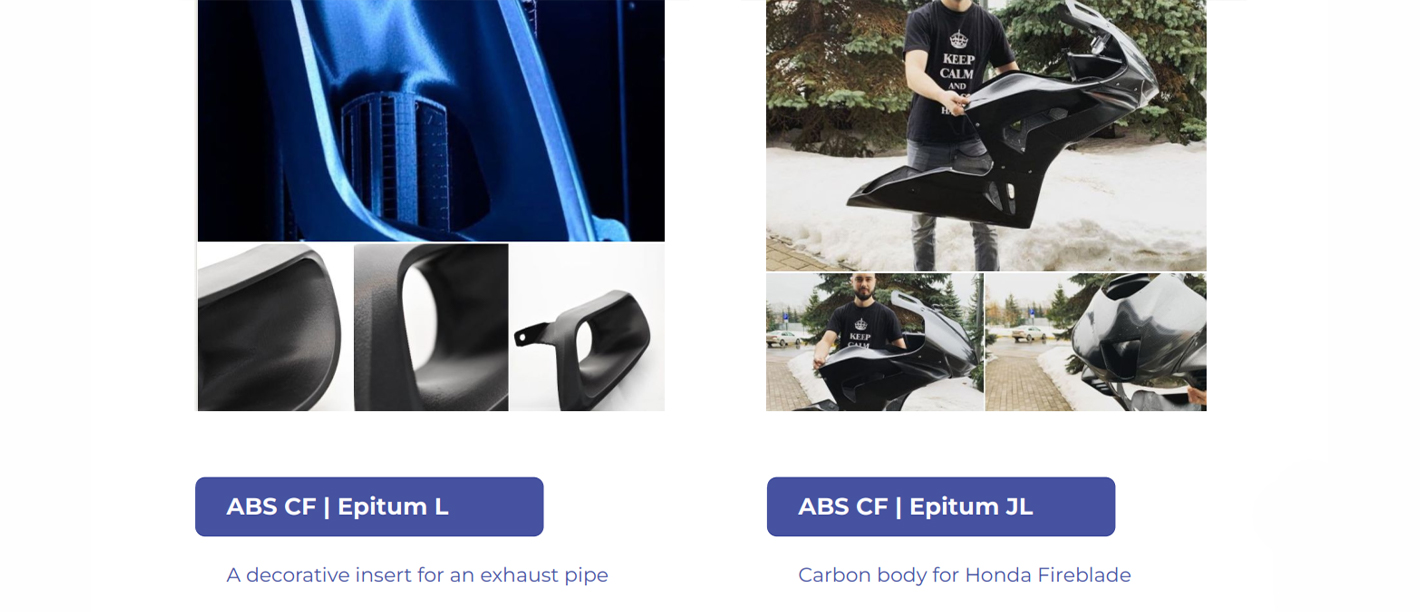

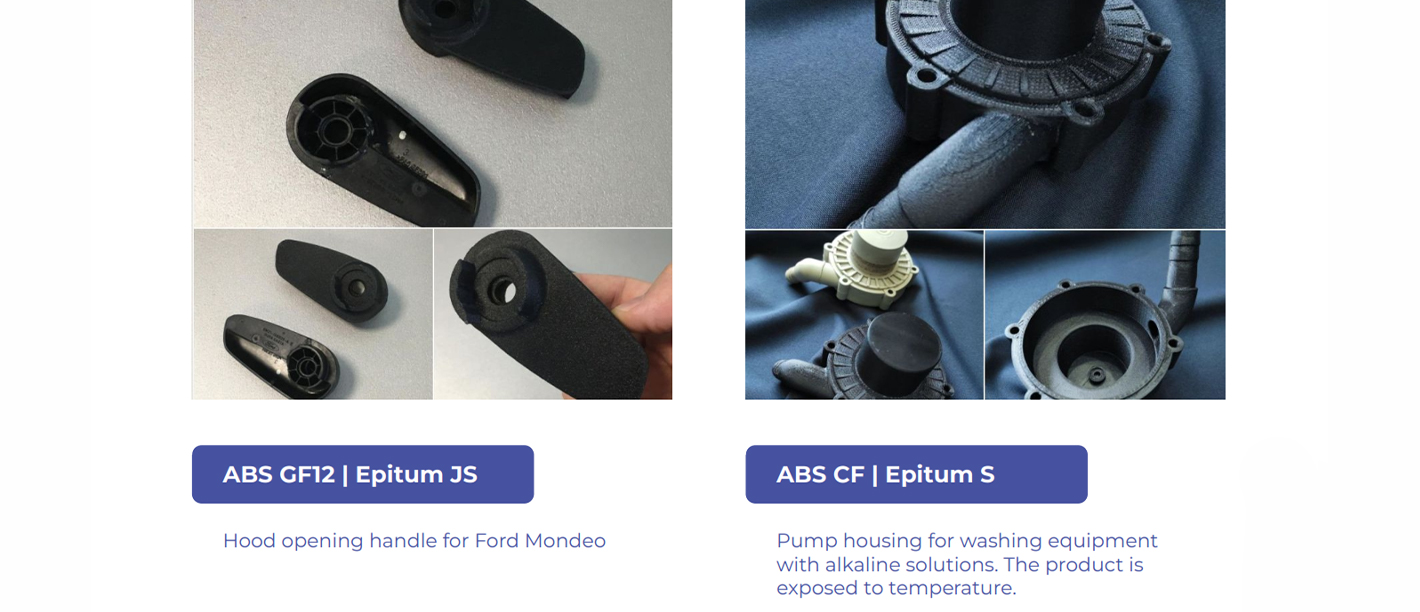

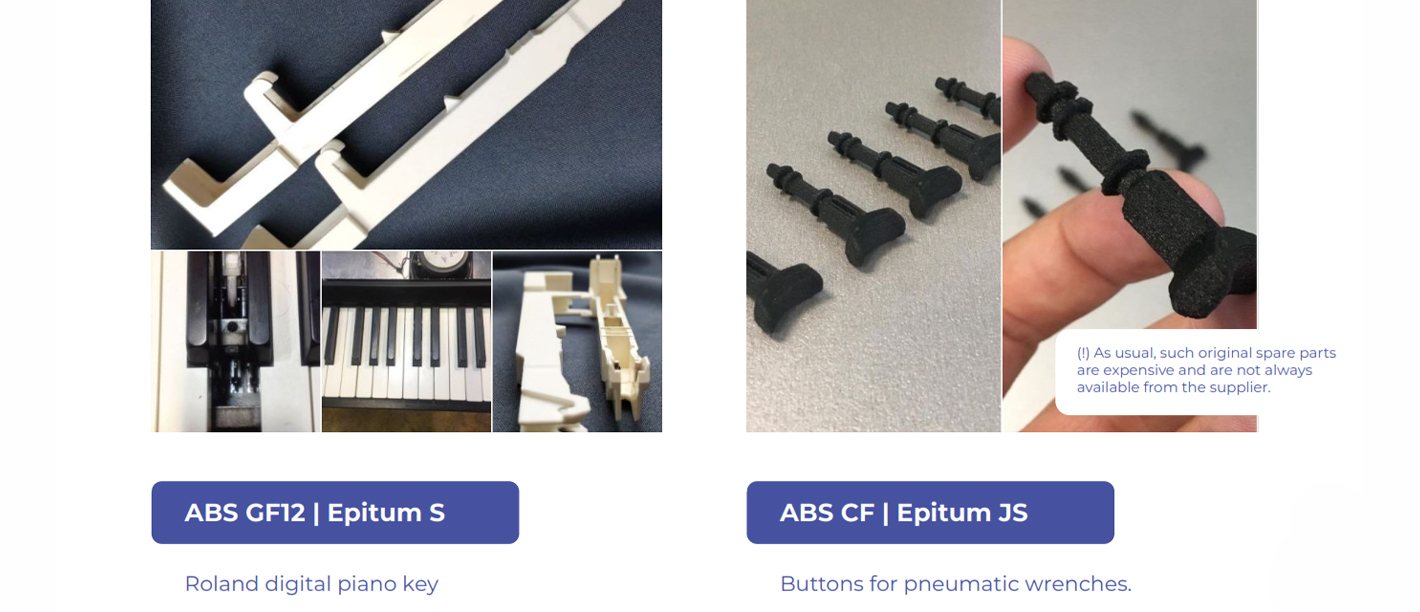

- Functional prototypes

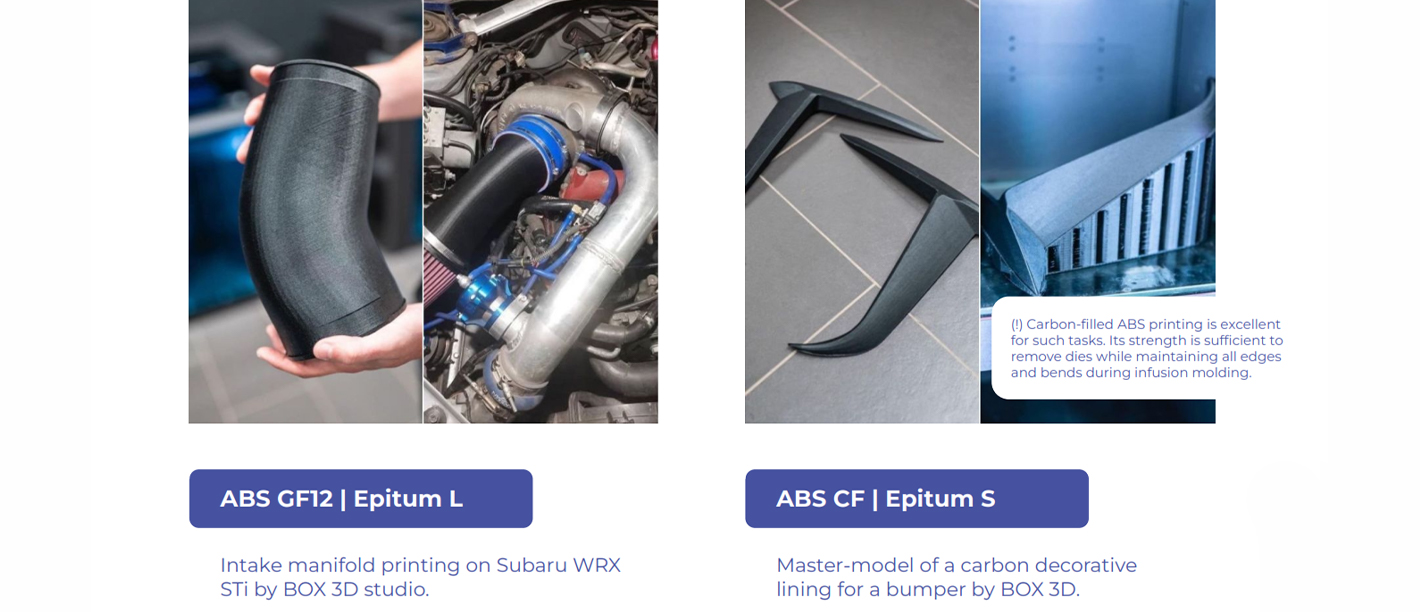

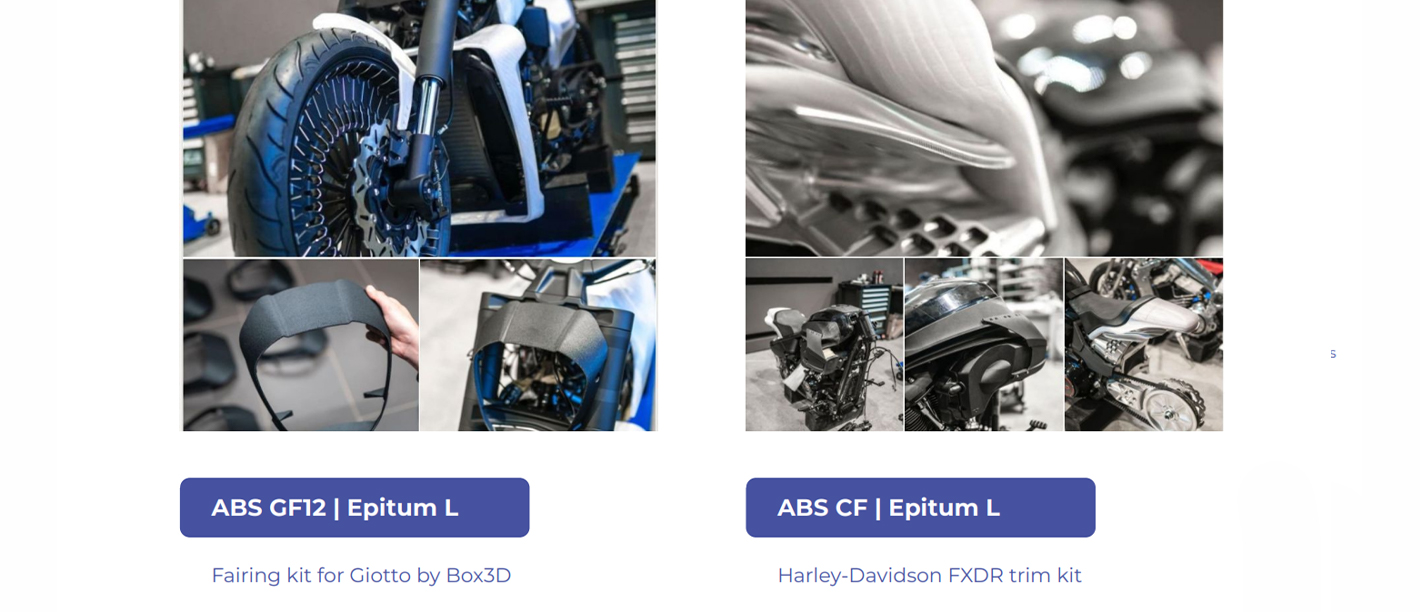

- Tuning. Small batch production

- Tooling

- Manufacturing of lightweight componant

AUTOMOTIVE INDUSTRY

Nothing speeds up automotive development and production faster than 3D printing.

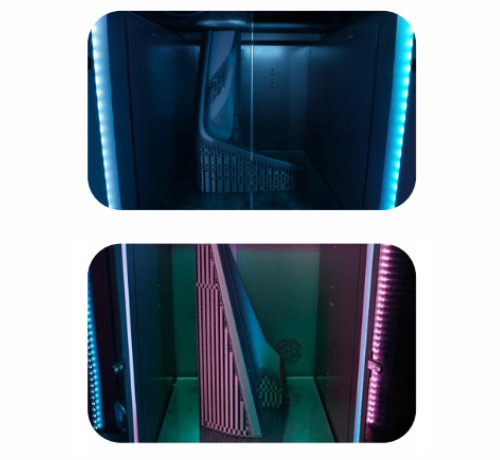

The 3D printing process itself takes only a couple of hours, and the finished prototype can be used to verify keyway geometry or serve as the finished car body or part.

The FFF technology has found a place in the automotive industry mainly because of its ability to use materials that are engineering-grade thermoplastics. Traditionally, additive manufacturing has been used for conceptual modelling and prototyping, but materials that can be printed using this technology open up new possibilities and applications.