Giulia Novars

TASK

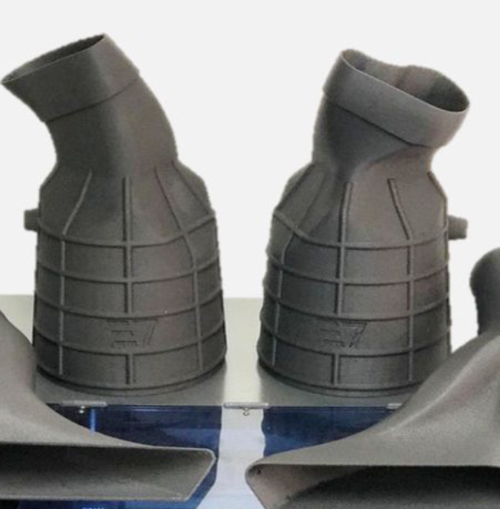

Creation of spare parts for the Swiss edge gluer, modernization of the Italian center for the processing of aluminum profiles, creation of parts for the Italian center for cutting panels, instrument cases and fittings.

SOLUTION

The necessary details are engineering, appearance and color are not so important. All you need to work is to have several coils of plastic with different properties on hand (ABS, SBS and PETG are enough for basic needs). In minutes, you can create a 3D model and start printing.

BENEFIT

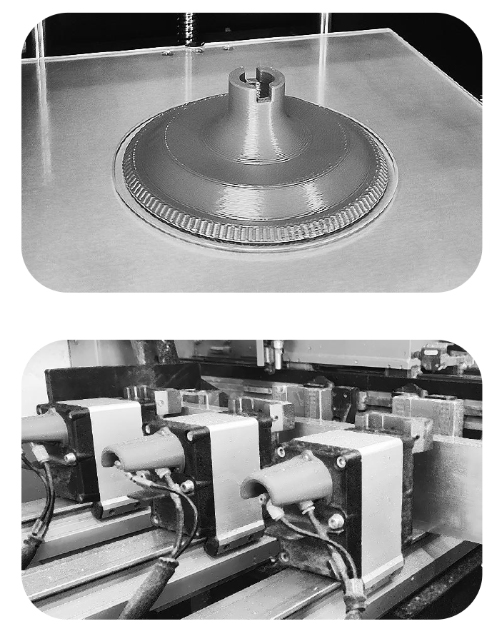

An alternative to 3D printing is turning and milling, preferably CNC. This is laborious, often requires a special tool or equipment, and most importantly, you need to have on hand a blank of the right material, the right shape and size. The ability to print the required part has become a lifesaver.

REVIEW

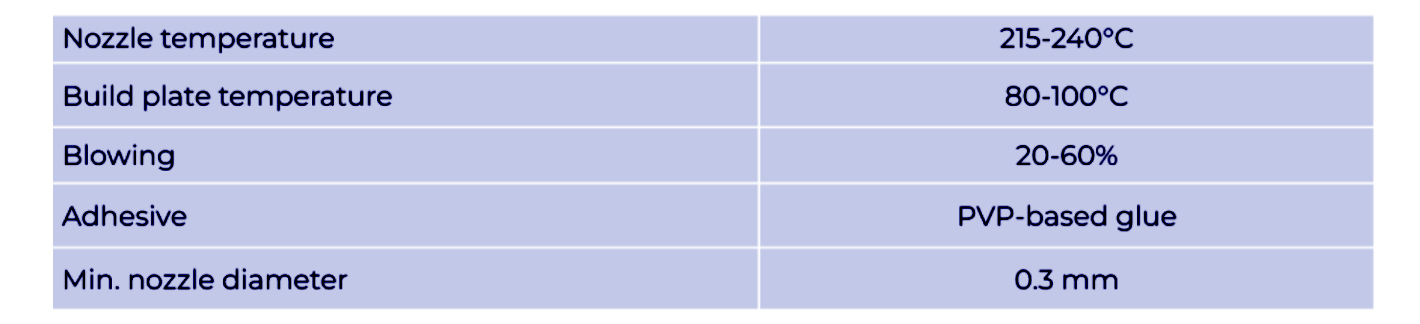

“If the physical properties of the printed part are sufficient (the main thing is to choose the right material), then 3D printing will be the best solution. At the moment, we are exploring plastics with special properties — Flex, TPU, ABS-CF, PA and the possibility of using them in our production. Each working day brings more and more new tasks, and, of course, the role and degree of participation of additive technologies in production will only increase.”