Inncellys GmbH

TASK

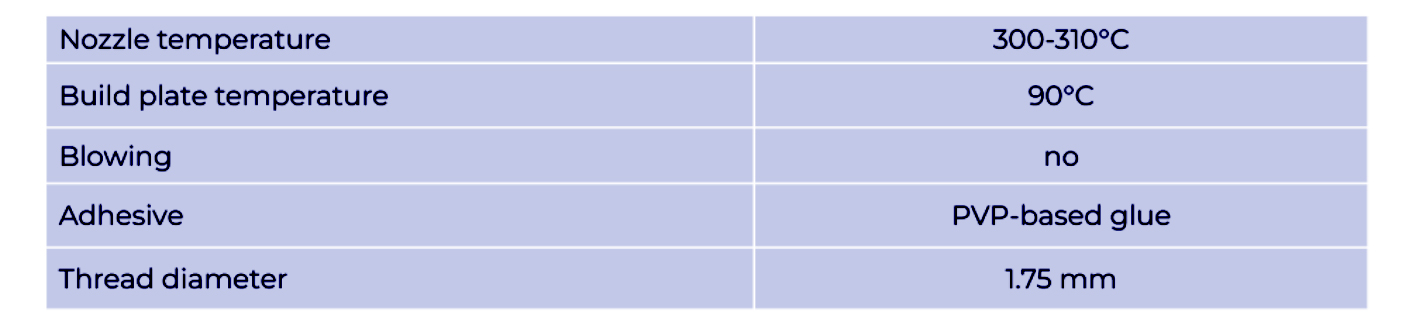

In order to produce more complex designs, we needed a 3D printer that could integrate soluble support structures into the printing process while maintaining the highest levels of printing accuracy and reproducibility. Reliable processing of biopolymers and high-performance polymers alike was another crucial requirement in order to be able to benefit from a wide range of material characteristics.

SOLUTION

The printing with soluble support structures, simple and fast adjustment procedures for bed levelling and print settings make starting and print jobs highly convenient.

BENEFIT

Rapid prototyping, easy way to produce chamber sets, bushings, covers, etc. The printing with soluble support structures significantly improved our printing time and printing results and decreases post-processing work.

REVIEW

“We are a young start-up and are just transitioning from prototyping applications to small series production. For both applications, 3d-printer allowed us to save time on supervising printing processes and dedicate more time for R&D, marketing and admin. We are now evaluating how network printing could increase our workflow efficiency.”